DVS - Drop Volume System

DVS - Drop Volume System for Precise Media Quantification and Process Control

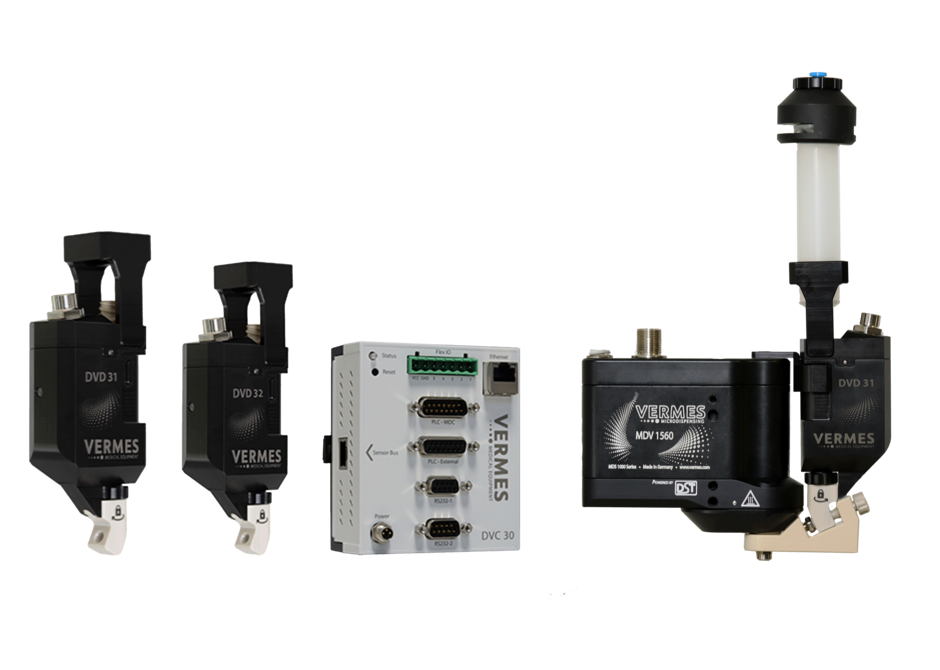

Each unit consist of: DVD + DVC (= DVS)

- DVD: Drop Volume Device

- DVC: Drop Volume Controller

The (Drop Volume System) DVS 31 and DVS 32 from VERMES Microdispensing sets a new benchmark in high precision media quantification microdispensing process. These advanced drop volume measurement systems are specifically engineered for real-time monitoring of low- to medium-viscosity fluids.

Ideal for GMP-regulated environments, the DVS ensures sub-1% deviation accuracy, supporting critical applications in life sciences, semiconductors, and electronics.

- Real-time Droplet Monitoring: Enables stable in-process measurement of single or burst dispensing

- Immediate Detection of Irregularities: Provides early detection of dispensing errors to minimize reject rates

- Accurate Fluid Volume Control: Achieves highly accurate volume analysis for process development and QA

- Seamless Integration: Effortless retrofitting via modular design, PLC/RS232 (machine to machine Interface (MMI)) interfaces

- User-friendly GUI: Browser based interface, and tool-free setup

- Compatibility: Fully compatible with wide range of VERMES with Piezo and non-Piezo systems and accessories

Application Areas:

Some areas of application for the DVS systems includes, but not limited to:

- Cell suspensions

- Protein solutions

- Fluxes, adhesives

- Lubricants, and more.

| Technical Data | |

| Recommended media | Low to medium viscosity up to 12,500 mPas (aqueous solutions, oils, alcohols, UV glue, etc.) |

| Max. supply pressure | Up to 12 bar |

| Operating temperature | 5°C - 50°C |

| Interfaces | RS-232C, Power Supply, PLC, Ethernet, Sensor Bus |

| Dimension | DVD 31 | DVD 32: 82.4 mm H x 26.0 mm W x 40.0 mm D Controller Unit DVC 30: 107 mm H x 95 mm W x 57.3 mm D |

| Weight | DVD 31 | DVD 32: 60 g Controller unit DVC 30: 203 g |

| Power supply | Controller unit DVC 30: 24 V/5 W DC |

© copyright 2025 VERMES Microdispensing GmbH