High Frequency Dispensing

with VERMES Microdispensing Jet Valves

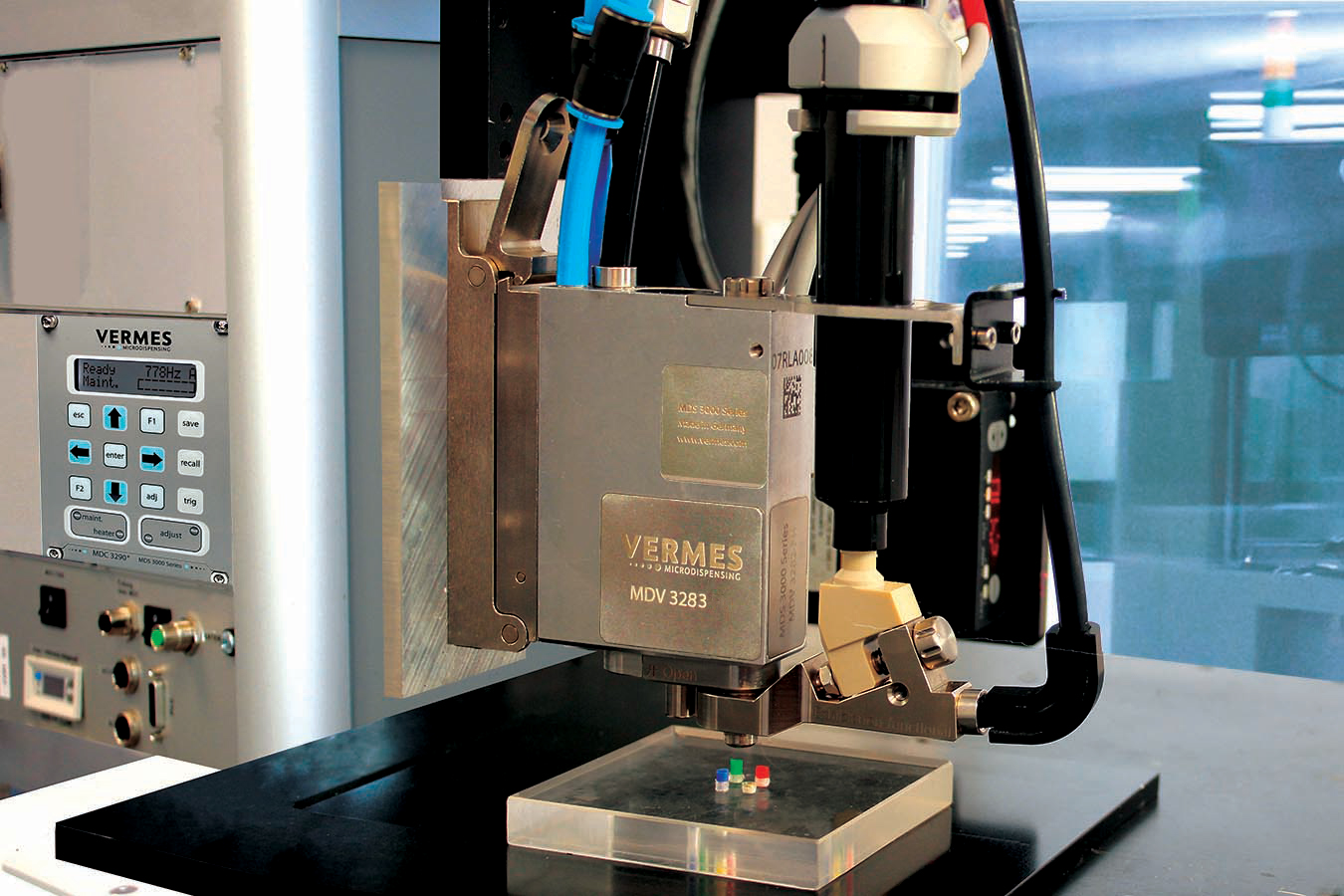

The latest high-frequency X3 series based on the two product families MDS 3283 and MDS 3253 is specifically designed for high throughput and reliability. They deliver the smallest dot sizes at the highest frequencies with maximum reliability in a wide range of dispensing applications.

- High dispensing frequency with the highest throughput

- Maximum deposition rate, precision and reliability

This unique product line of the X3 series offers the best solution to close the current market gap in terms of highest throughput and precision. Industry sectors, such as consumer electronics, medical or automobile strive to bring new products to market in ever shorter cycles.

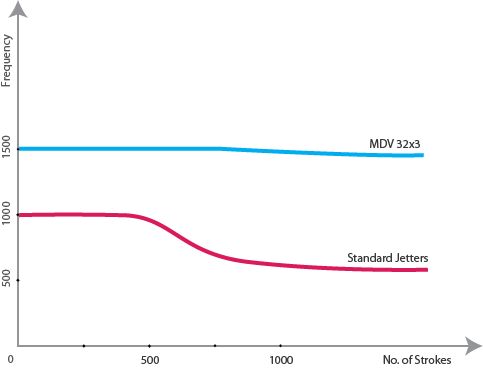

constant performance at high frequency

Major Advantage

The areas of application for this new X3 series is extremely diverse. 3D printing pastes with fillers made of metal or ceramics, silicone printing in the automotive, healthcare, electronics & lifestyle sectors, overspray-free 2D painting, low-viscosity metallic pastes for solar cells, and circuit board printing are just a few more examples where high-speed dispensing with the smallest drop sizes and absolute constant results are essential.

This new valve series from VERMES Microdispensing are able to dispense media of the highest viscosity for example varnishes and paints that contain solid particles such as pigments.

It is perfect for applications that require a high resolution combined with the highest throughput, such as 2D and 3D printing. It bridges the gap left by the existing technologies in the market, which can only cope with low viscosity media such as ink.

The X3 series incorporates a highly effective frame design and optimized cooling system that dissipate unwanted temperatures and comes with an integrated heater and cooling, thus ensuring the optimal process temperature that is required for each individual medium due to its special nature and viscosity.

The enhanced features of the new series achieve constant dispensing performance at the highest frequency and ensure not only perfect calibration and control at a viscosity up to 2,000,000 mPas but also a throughput that is far loftier than any system that is currently available on the market. These piezo-technology-based jetters operate contact-free and can take any challenge such as layer-by-layer printing processes when dispensing into the smallest cavities where the valve needs to move laterally and vertically in discrete increments.