Microdispensing systems (MDS) - Highest precision and speed

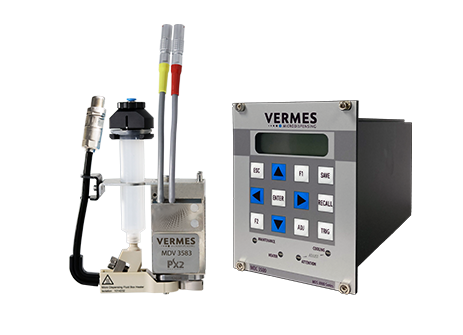

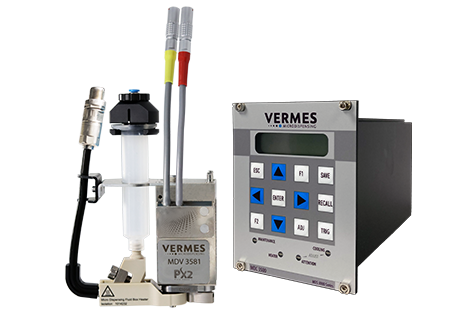

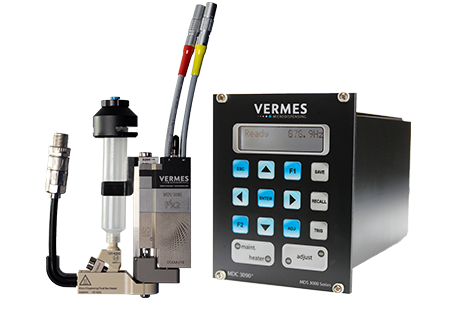

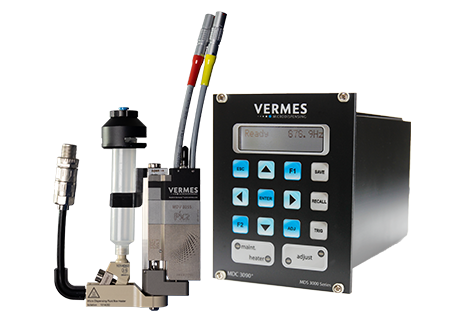

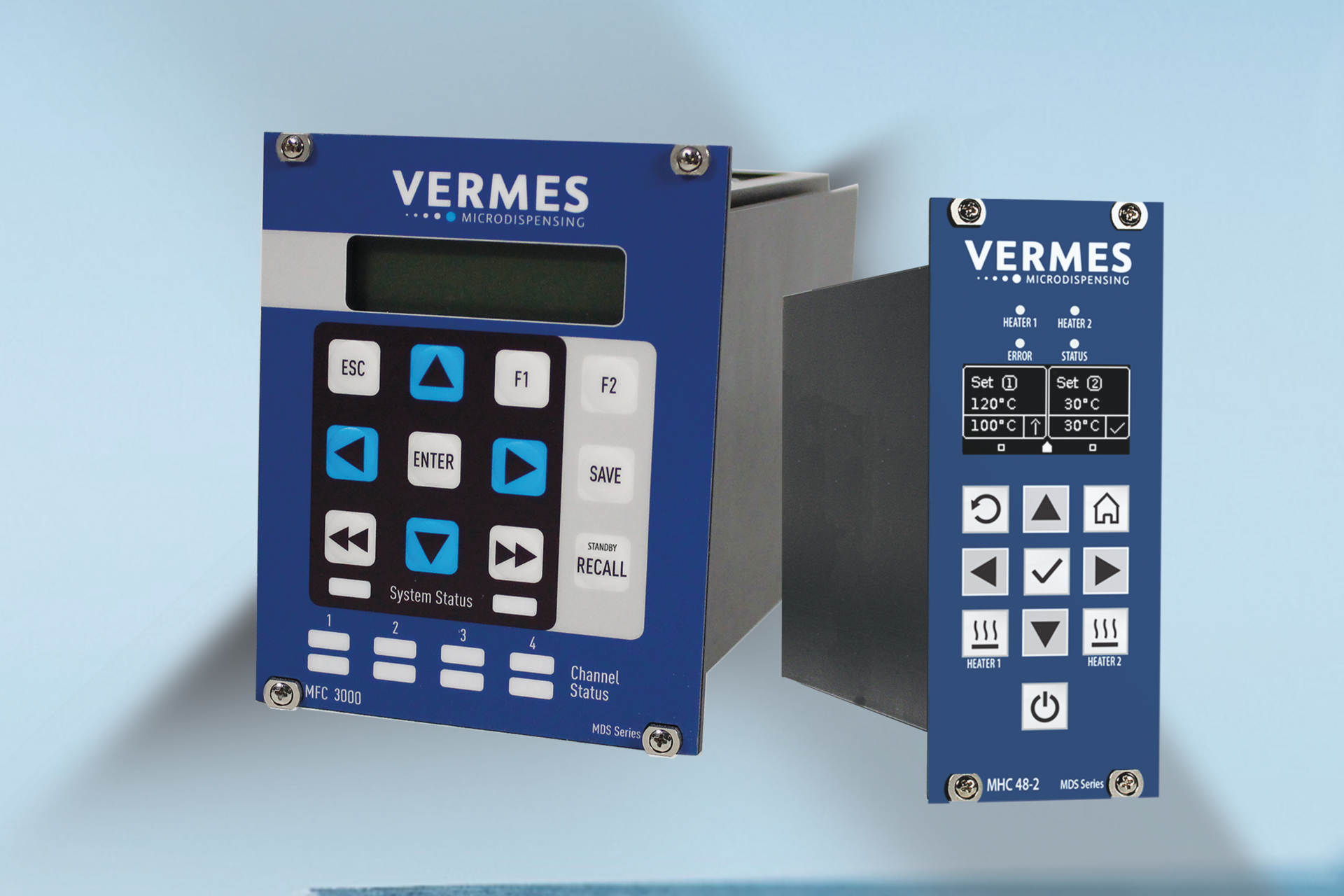

The microdispensing systems of the MDS 15xx, 32xx, 30xx and 35xx product series from VERMES Microdispensing set new standards in contact free dispensing technology. They offer exceptional speed and accuracy, making them the ideal solution for modern manufacturing processes.

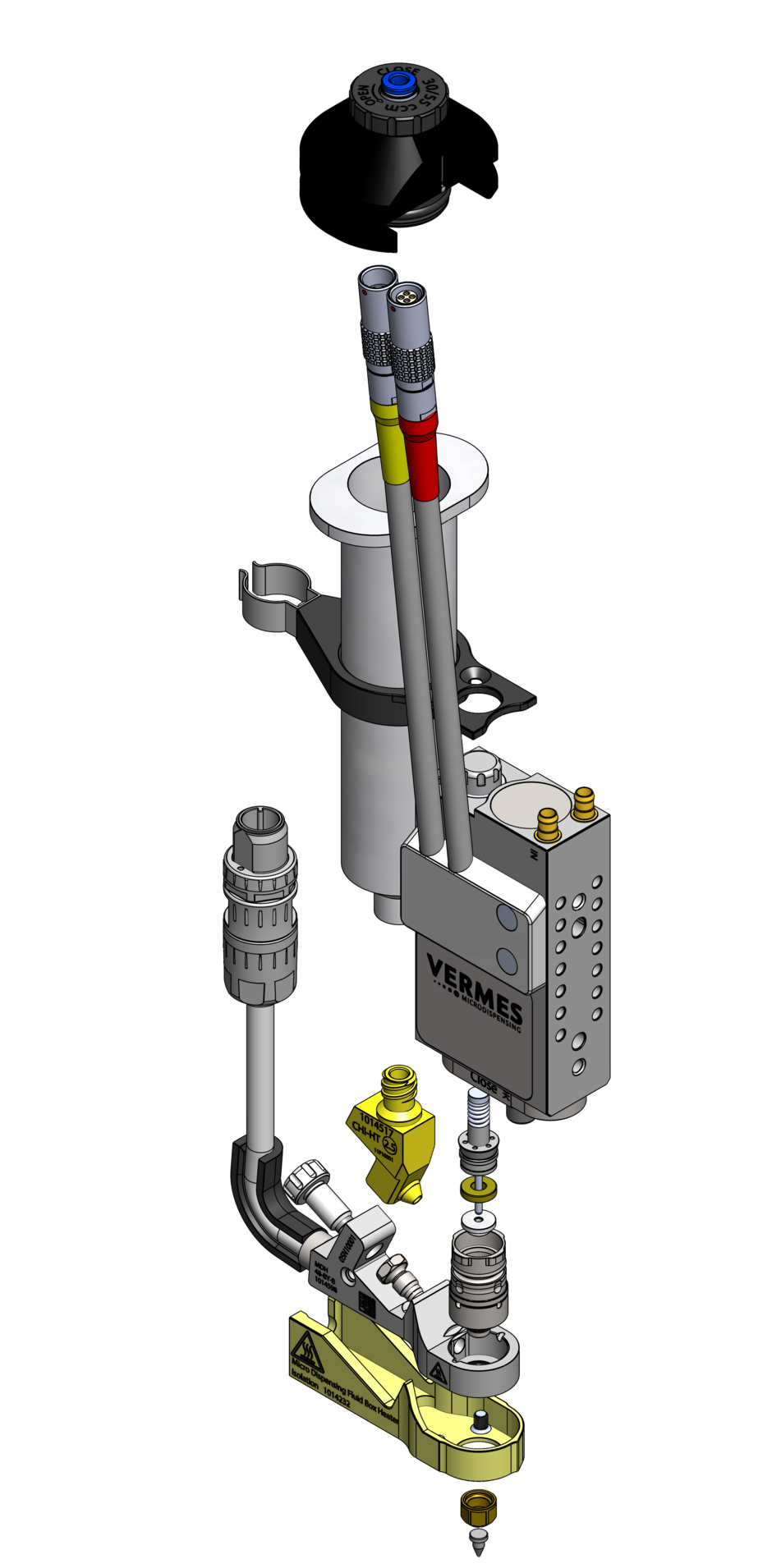

Components of a microdispensing system

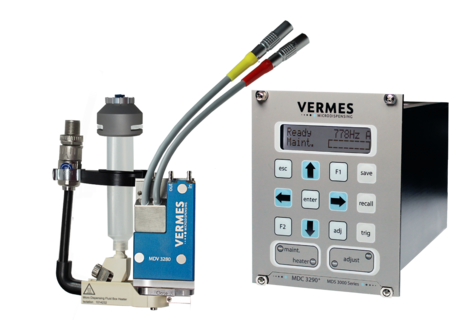

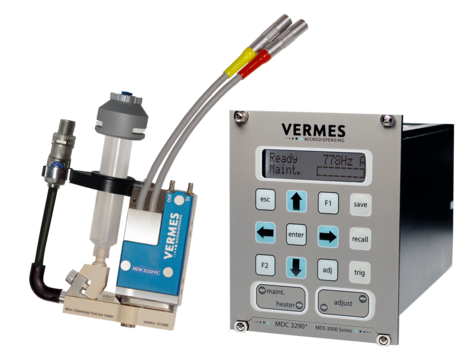

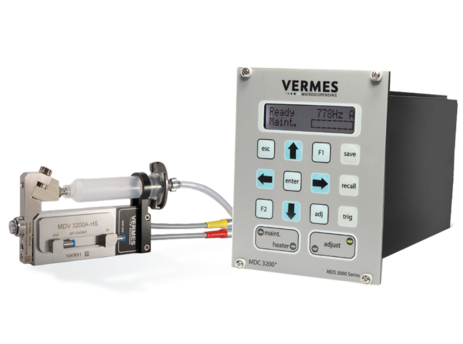

At VERMES Microdispensing, a MicroDispensing System (MDS) consists of two central components:

- the MicroDispensing Valve (MDV)

- the MicroDispensing Controller (MDC)

This combination enables the precise control and dispensing of very small quantities of liquid - contactless, fast and economical.

Indispensable for modern production processes

Advances in miniaturisation are making contactless microdispensing systems indispensable - they ensure precise, repeatable and reliable dispensing for modern manufacturing processes.

With microdispensing systems from VERMES Microdispensing, you are ideally equipped to solve even the most demanding dispensing tasks efficiently and precisely.