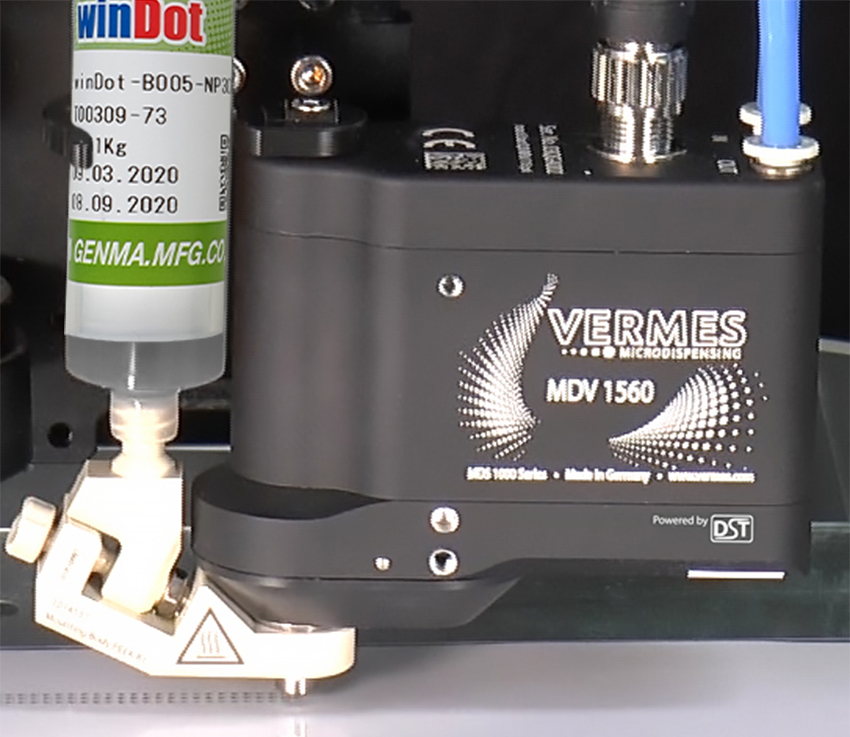

Holzkirchen / Stuttgart, Germany, September 08th, 2020- The recent collaboration between VERMES Microdispensing - a leader in design and manufacture of innovative microdispensing systems and GENMA - a world-renown high-quality solder paste manufacturer, resulted in a new application for a fast and reliable process to apply smallest solder paste quantities in electronics manufacturing.

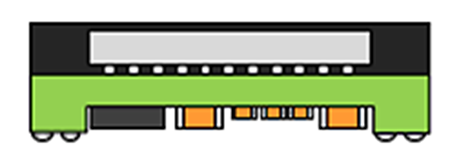

One of the main areas for solder paste dispensing is the mounting of electronic components in the PCB (Printed Circuit Board) assembly. Another major area is the use in module packaging. Both processes require the highest dispensing quality and steadiest process conditions.

Many systems available on the market rely on old technologies that cannot meet today’s market requirements for higher operating speed with smaller drop size.

Contrarily, the VERMES Microdispensing systems are based on so called jetting valves with which the material can be applied contact free and with high speed and high precision.

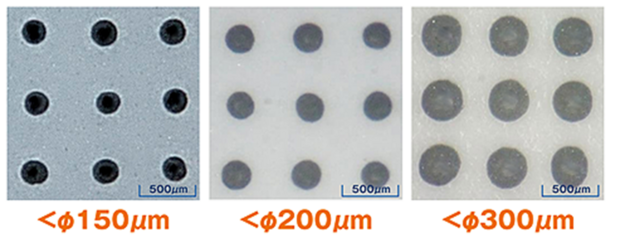

“GENMA continuously searches for improvement and new technical solutions for our customers. In cooperation with VERMES Microdispensing we can now offer an outstanding solder paste solution, solving current technical challenges. GENMA’s winDot solder paste can be consistently and safely applied in a dot size as small as 130μm in automated production processes,” states Stefan Komenda, CEO of GENMA Europe.

“The advantages of the VERMES Microdispensing System MDS 1560 that is based on our revolutionary actuator principle technology - DST (Dynamic Shockwave Technology) combined with GENMA winDot solder paste provide our customers with optimal solder paste dispensing results even at the smallest drop size,” adds Juergen Staedtler, CEO of VERMES Microdispensing.

The VERMES Microdispensing System MDS 1560 can easily be integrated into in numerous machine platforms, such as dispensing robots and screen printers.

High-end design and increased functionalities require electronics to get continuously smaller. The new VERMES MDS 1560 system with its optimized dispensing characteristics in combination with GENMA’s winDot solder paste allows jetting small dots in an absolutely reliable process at a high speed. Besides speed and dot size, reliability is specifically important. The new jetting process offers a solution that provides continuous top results. The valve can jet more than 1 million dots in a row without the necessity of operator attention.

In electronics manufacturing, the solution easily performs solder paste dispensing of smallest dot sizes and can increase the density on boards. The GENMA winDot solder paste can be jetted to pads for the smallest chip component currently in use, which is known as a 01005.

In prototyping and small-scale production the VERMES Microdispensing System MDS 1560 in combination with the GENMA winDot solder paste is much more productive than stencil printing.

In mass production, the solution is an ideal addition to filling up solder depots or add additional depots.

Where it is not possible to print small solder paste depots, such as with flexible PCBs and 3D-MIDs (3-Dimensional Molded Interconnected Devices production), the system solution offers the fastest and most precise way of applying solder paste.

Without doubt, the jetting technology is sustainably faster than needle dispensing and pin transfer and delivers more precise results.

The higher accuracy considerably increases the production yield compared to the currently used solder paste application methods. A small dot size combined with highest reliability and high speed also provide great advantages to module packaging, such as PoP (Package on Package) modules, CSP (Chip Scale Packages) modules , 3D printed circuit boards, and for mounting RF Shields.

À propos de nous

VERMES Microdispensing, dont le siège social est en Allemagne, a révolutionné la technologie du microdosage en 2001 avec l'introduction de la série MDS 3000 sans contact à base de piézo. Aujourd'hui, l'entreprise est leader mondial dans le développement et la fabrication de concepts et de systèmes de microdosage innovants pour les adhésifs, les silicones et les graisses, les pâtes à braser, les colles conductrices à l'argent, les solvants et autres liquides.

Les valves de haute précision des séries MDS 1000 et MDS 3000 de VERMES Microdispensing soutiennent les processus de fabrication modernes dans le monde entier, par exemple pour les composants MEMS, les semi-conducteurs, les écrans (LCD, OLED, Micro-LED), les smartphones, l'automobile et la pharmacologie, le SMT, les puces RFID et de nombreux autres appareils électroniques.

Une base de connaissances unique au monde, une compétence inégalée en matière de conception et une capacité de fabrication étendue permettent à l'entreprise de réagir rapidement et efficacement aux conditions changeantes du marché et aux besoins individuels des clients.

Nos systèmes permettent aux clients d'atteindre des tailles de gouttelettes de l'ordre du micro, du nano et du subnanolitre lors du dosage sans contact de produits très visqueux, à des fréquences théoriques de plus de 3000 Hz ; une valeur unique dans notre industrie.

Les collaborateurs de VERMES Microdispensing s'engagent à offrir à leurs clients du monde entier les meilleures technologies et les meilleurs services. Leur objectif principal est de contribuer à l'augmentation de la productivité, à l'amélioration de la qualité et à la réduction des coûts de production.

Pour plus d'informations sur VERMES Microdispensing, consultez le site www.vermes.com. VERMES Microdispensing est une marque déposée de VERMES Microdispensing GmbH en Allemagne et dans d'autres pays.

D'autres marques, non mentionnées ici, peuvent être la propriété de tiers.

Contact

Marco Golla

VERMES Microdispensing GmbH

Rudolf-Diesel-Ring 2

83607 Holzkirchen

Germany

Phone:+49 (0) 80 24-6-44-335

Fax: +49 (0) 80 24-6-44-19

pr@vermes.com

www.vermes.com